Transport activities in the AGV system are treated as orders. Typically, an order defines a transport task between two pre-configured positions or stations. Once initiated, the order triggers a sequence of predefined transport operations configured by the system designer within the AGV Control System. Transport orders are usually auto-generated using one of the following methods:

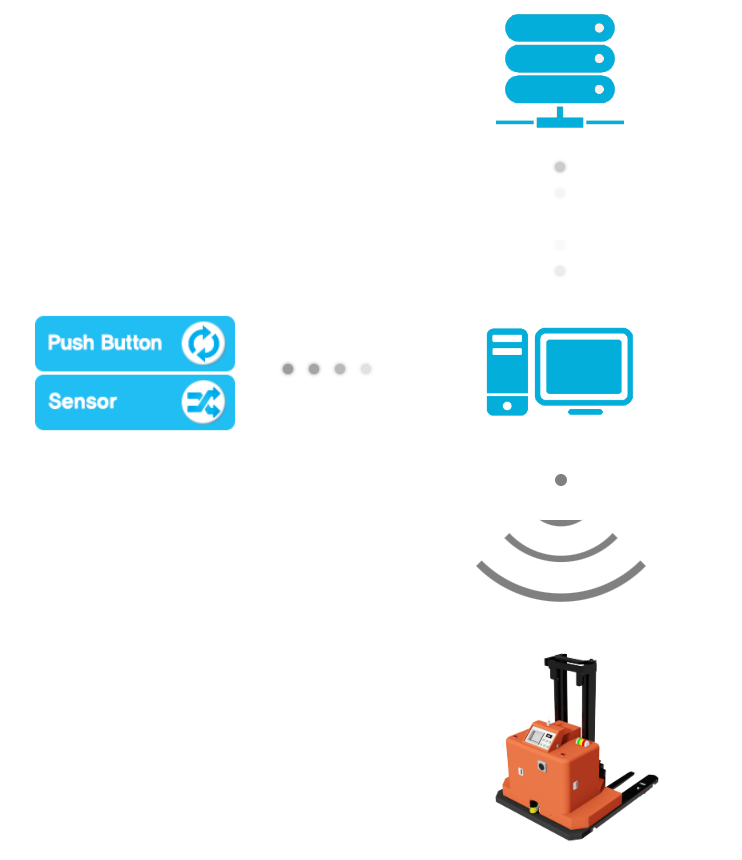

- A. Push-button or Sensor

- Activating a push-button or sensor input triggers a transport request. These input devices are generally wired directly to the AGV control system or interfaced via an I/O module.

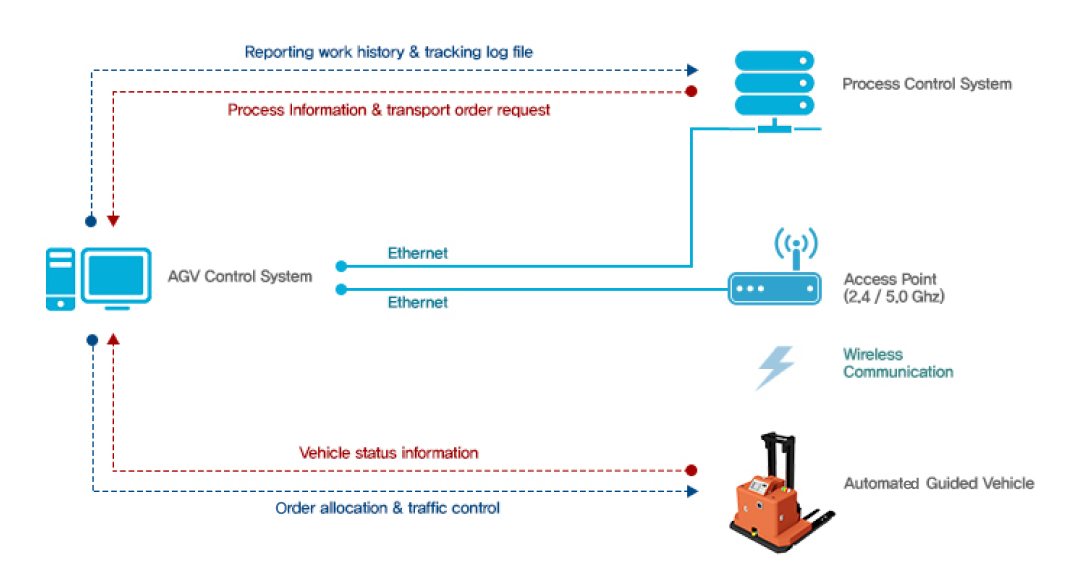

- B. Host System

- An integrated host system such as MES (Manufacturing Execution System), WMS (Warehouse Management System), or ERP (Enterprise Resource Planning) can generate transport orders. These systems communicate with the AGV Control System via standard industrial communication protocols over the network to initiate transport sequences.